AI solutions in Industry

We provide many different solutions in all fields by applying artificial intelligence technology and computer vision to support digital transformation until we reach the highest peaks of development and progress

Artificial Intelligence Services in manufacturing:

- Enabling the transformation of smart manufacturing

Bringing productivity apps together with smart cloud services and security to transform the way you work.

- Build factories faster

Creating production lines using information technology, operational technology and industrial internet of things

- Create supply chains

Smart Optimize digital operations with smart business applications that help strike the right balance between customer service and supply chain cost.

- Unleash creativity

Introduce new services Preparing manufacturing visualization while accelerating innovation through insights from predictive analytics.

Advantages of applying artificial intelligence in manufacturing:

Avoid downtime and improve productivity.

- Extending the life of assets and making new purchases.

- Reducing the cost and complexity of repairs.

- Mitigation of additional or related damages.

- Meet regulatory standards and comply with regulations.

- Managing spare parts, materials and inventory.

- Enhance results.

Automation of production processes

- self-improvement and maintenance Monitor and determine equipment effectiveness (OEE).

- Analyzing production line quality data.

- Supply chain management.

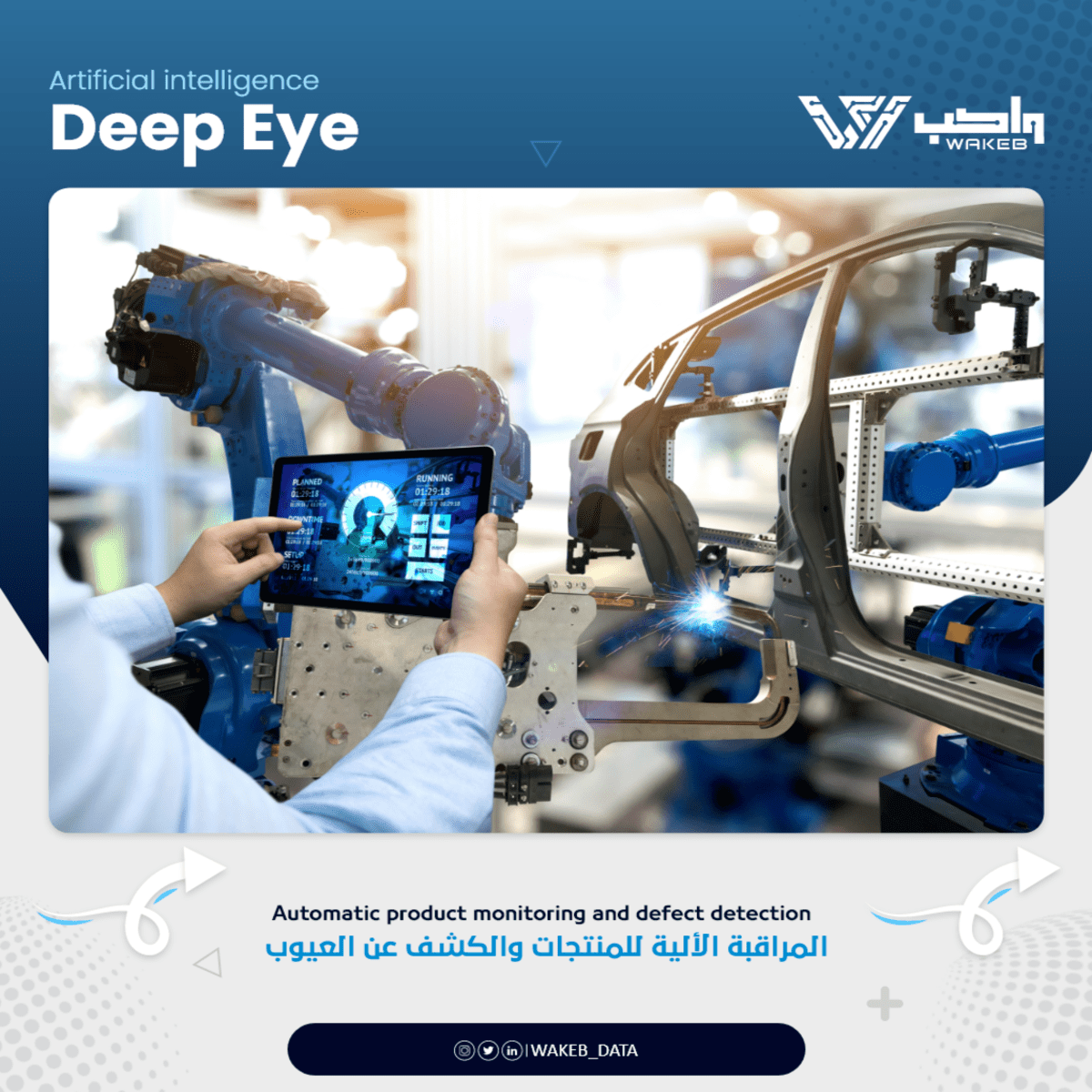

Automated monitoring and defect detection

- Using probe technology to determine production quality Detection of production defects.

- Identify products and objects.

- The number of product units.

- Automated inspection of production equipment.

Detecting faults and defects.

- Quality check and confirmation.

- Integration and improvement of assembly lines.

- Inventory Management. Supply chain planning and supply.

Artificial intelligence applications in manufacturing:

Factories require high accuracy and quality so we offer deep Eye ai-based system to enhance factory safety and security as well as monitor and improve production lines

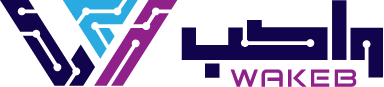

What is Deep Eye?

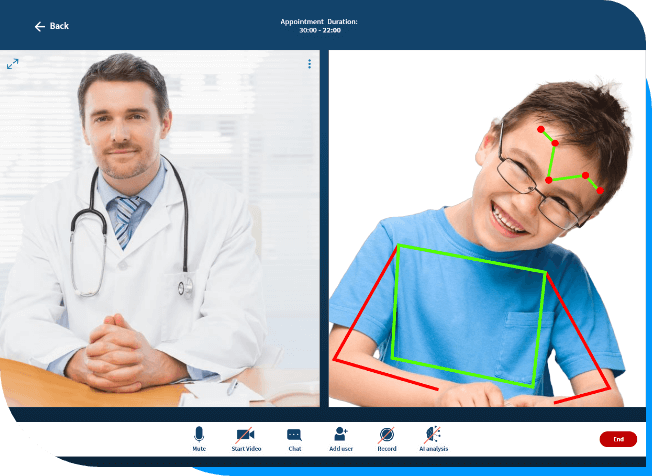

It is a smart system that is connected to surveillance cameras for drones that automates product monitoring processes, detects defects, reports any defects or problem and warns about them immediately through the system and monitors the applications of workers' security and safety guidelines and standards through surveillance cameras for drones all this and more to help you reduce operating costs and monitor the working situation in advance

What Deep Eye offers:

First: Production lines

- Identify measurements and dimensions

- Counting and counting

- Inspection, quality and detection of defects

- Speed control

- production lines

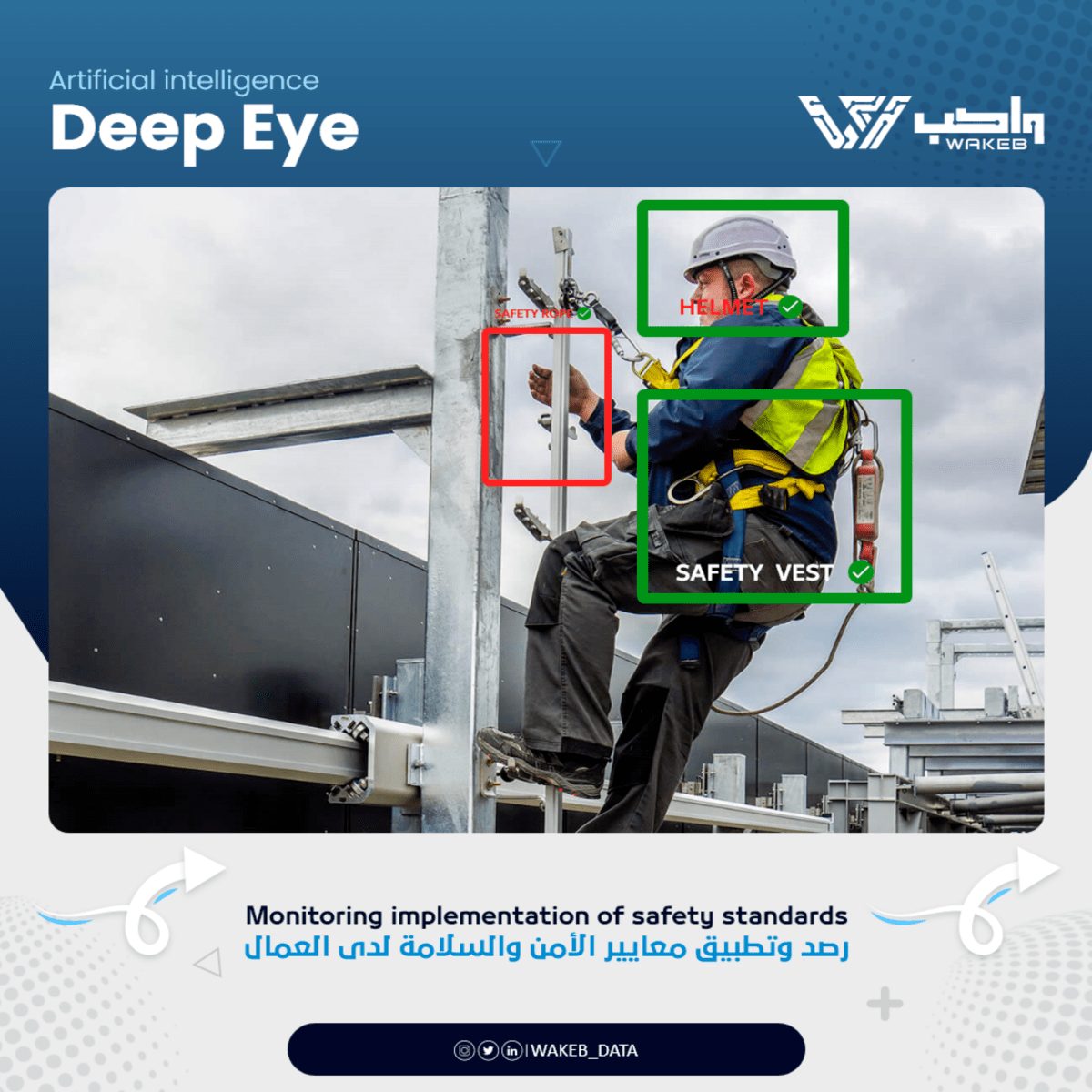

Second: Protection and safety

- Gloves

- Speed of vehicles and cranes

- Face mask

- Fluid infusion

- Protective shoes

- Muzzles

- Protective vest

- Fires and smoke

- Protective glasses

Deep Eye features:

- Controlling violations Integration with other systems Production accounts

- Reports and statistics

- Control panel

- Instant alerts

Start using AI for enterprises to ensure quality manufacturing with deep learning, drive decision-making and gain valuable insights that allow you to see and understand things that human operators couldn't see in the past.

Contact us now